Loose steering bearings

My steering stem bearings loosened up. It started a while ago but I didn't know that's what it was. It looked like only the front wheel was moving so after a telephone consultation with the Moto-hubby, he suggested I go ahead and get the front wheel bearings done. Got them done but the problem persisted. I thought it just might have been the nature of the R1 swap because it was only slight movement that I only noticed when I physically moved the wheel. Well, this weekend after i hit a massive pothole, the hole front end started moving under braking!

I was ready to drive off of the mountain thinking about the monumental mistake I made and how I should have listened to everybody and left well enough alone. Feeling morose, I decided to slab directly home. Cruzman looked at the bike and diagnosed it as loose steering stem. I was relieved but still morose. He said we could tighten it then but I told him no. I paid a professional to install it so the professional would fix it.

I called Lorne @ OTC on Monday and he said no problem, it'd only take a few minutes to tighten it up and I could stop by any time they were open. Took it yesterday and watched as he tried to get it tight enough but couldn't. He had help from a guy who is an AMA mechanic who just happened to be in there when I showed up. (dude with his back to the camera)

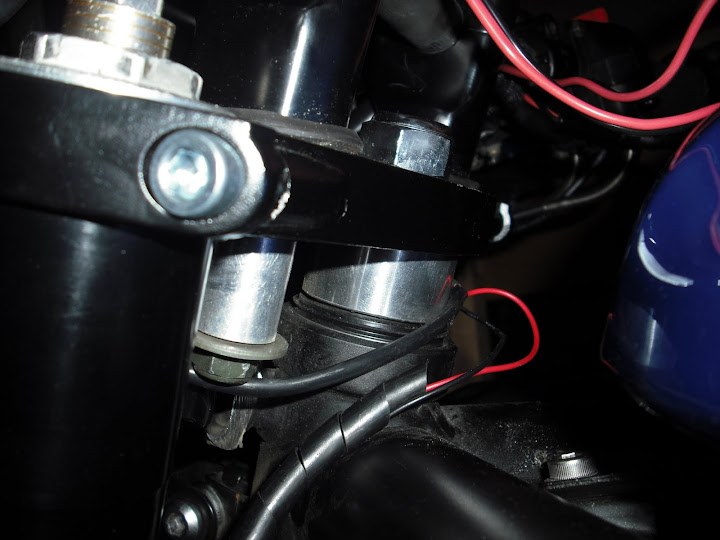

After some cursing and discussions, they decided there must be a piece missing because they couldn't get it tight enough. Cruzman texted me a couple of pics of his steering bearings and we discovered that I was missing the silver cap peice. It was on the bike when I took it in, but not when I got it back. The bolts are just resting on the rubber cap thingie that comes with the kit. AMA mechanic guy (I never got his name) said that it was putting too much pressure on the head bearings.

Lorne agreed to replace the bearings and get a new silver thingie. So instead of this:

It should look like this:

Cruzman is certain that collar doesn't hold any weight. I agree but it does add width or space to the setup and will likely take up the room that's needed to get the screws properly tight. I think Lorne thought it was apart of the roller bearing seal kit because the cap for it and the cover were stuck together. Either way, it's getting fixed along with the leaking left (when sitting on the bike) fork seal that developed during the trip.

I also got the extensions off. Lorne is going to change my front tire for free as well and will help me get the extensions measured to get cut down if it's still needed when I install the gen2 upper triple.

I didn't think doing the final touches would take me this long. I guess the delay was for the best considering what's happened.

My steering stem bearings loosened up. It started a while ago but I didn't know that's what it was. It looked like only the front wheel was moving so after a telephone consultation with the Moto-hubby, he suggested I go ahead and get the front wheel bearings done. Got them done but the problem persisted. I thought it just might have been the nature of the R1 swap because it was only slight movement that I only noticed when I physically moved the wheel. Well, this weekend after i hit a massive pothole, the hole front end started moving under braking!

I was ready to drive off of the mountain thinking about the monumental mistake I made and how I should have listened to everybody and left well enough alone. Feeling morose, I decided to slab directly home. Cruzman looked at the bike and diagnosed it as loose steering stem. I was relieved but still morose. He said we could tighten it then but I told him no. I paid a professional to install it so the professional would fix it.

I called Lorne @ OTC on Monday and he said no problem, it'd only take a few minutes to tighten it up and I could stop by any time they were open. Took it yesterday and watched as he tried to get it tight enough but couldn't. He had help from a guy who is an AMA mechanic who just happened to be in there when I showed up. (dude with his back to the camera)

After some cursing and discussions, they decided there must be a piece missing because they couldn't get it tight enough. Cruzman texted me a couple of pics of his steering bearings and we discovered that I was missing the silver cap peice. It was on the bike when I took it in, but not when I got it back. The bolts are just resting on the rubber cap thingie that comes with the kit. AMA mechanic guy (I never got his name) said that it was putting too much pressure on the head bearings.

Lorne agreed to replace the bearings and get a new silver thingie. So instead of this:

It should look like this:

Cruzman is certain that collar doesn't hold any weight. I agree but it does add width or space to the setup and will likely take up the room that's needed to get the screws properly tight. I think Lorne thought it was apart of the roller bearing seal kit because the cap for it and the cover were stuck together. Either way, it's getting fixed along with the leaking left (when sitting on the bike) fork seal that developed during the trip.

I also got the extensions off. Lorne is going to change my front tire for free as well and will help me get the extensions measured to get cut down if it's still needed when I install the gen2 upper triple.

I didn't think doing the final touches would take me this long. I guess the delay was for the best considering what's happened.

Last edited: