Broke_Dirty_FZ1

Well-Known Member

I doubt you guys have the same tools in your garage that I do, but I thought you guys would get a kick out of this nonetheless.

My rear tire failed state inspection so I decided to get new rubbers all the way around, because I wanted to replace the rear with a Pilot Road 2 and I don't like to mismatch manufacturer's tires.

So of course, I set out to save bookoo money by pulling the wheel assemblies off and taking them to the shop instead of letting them charge me full price for R&R.

Back wheel comes off, no problem. I've done it before and I have all the tools. I go to get the front wheel off and I realize I don't have the huge allen type driver to remove the front axle. The biggest one I have is 17mm. So there I am, thinking I will either just take it to the dealer after all, or go and have to buy a special tool for $30 or $40, severely dipping into my new found savings.

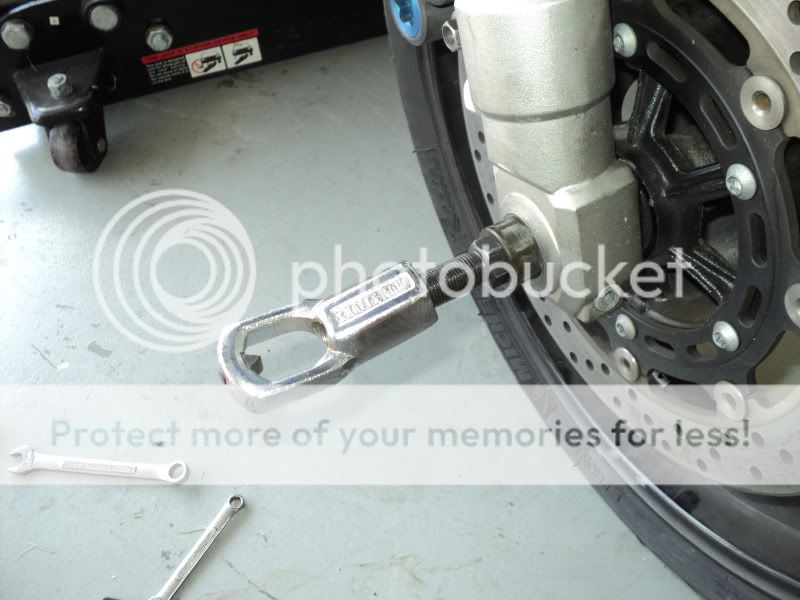

BUT! I get to looking through my tool box when I realize I have this. A craftsman nut splitter and the part that you wrench on just happens to be the exact same size as the axle.

So I pull that threaded piece off and use a crescent wrench on the still exposed head to remove the axle, because I also don't have a wrench that big, and I don't have a deep well socket that is that size either.

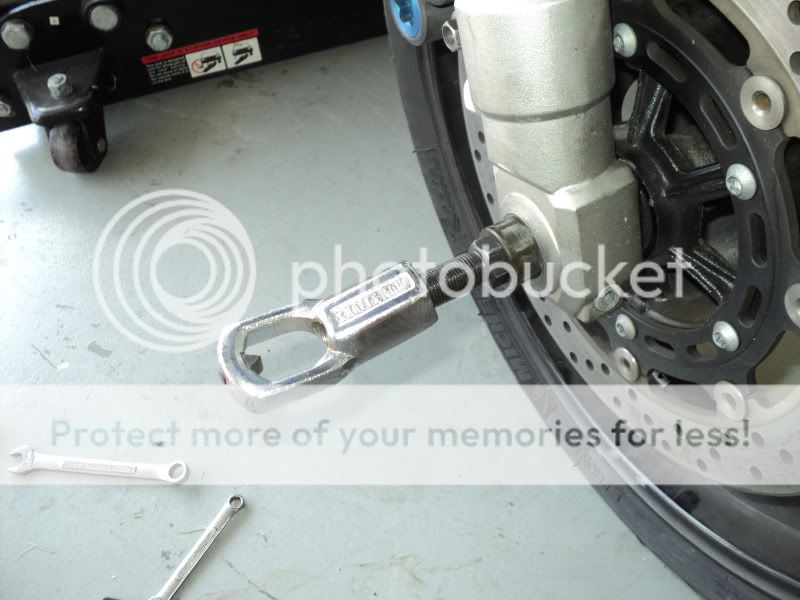

Next, before going home with my new tires, I stop by Harbor Freight to get the proper socket or a crows foot so I can torque the bad boy back on. No go, the biggest they have is 17mm and only in complete sets. I get back home and realize that the threaded side fits completely into the axle.

Which allows me to do this, and put the torque wrench on there.

I couldn't believe my luck.

My rear tire failed state inspection so I decided to get new rubbers all the way around, because I wanted to replace the rear with a Pilot Road 2 and I don't like to mismatch manufacturer's tires.

So of course, I set out to save bookoo money by pulling the wheel assemblies off and taking them to the shop instead of letting them charge me full price for R&R.

Back wheel comes off, no problem. I've done it before and I have all the tools. I go to get the front wheel off and I realize I don't have the huge allen type driver to remove the front axle. The biggest one I have is 17mm. So there I am, thinking I will either just take it to the dealer after all, or go and have to buy a special tool for $30 or $40, severely dipping into my new found savings.

BUT! I get to looking through my tool box when I realize I have this. A craftsman nut splitter and the part that you wrench on just happens to be the exact same size as the axle.

So I pull that threaded piece off and use a crescent wrench on the still exposed head to remove the axle, because I also don't have a wrench that big, and I don't have a deep well socket that is that size either.

Next, before going home with my new tires, I stop by Harbor Freight to get the proper socket or a crows foot so I can torque the bad boy back on. No go, the biggest they have is 17mm and only in complete sets. I get back home and realize that the threaded side fits completely into the axle.

Which allows me to do this, and put the torque wrench on there.

I couldn't believe my luck.